Automation, digitization, and AI have been actively transforming workflows in various industries over the past decade. Quality control remains a key stage in these processes across all fields. Certainly, real-time monitoring has relied on humans for a long time, which is valuable but unfortunately error-prone. To ensure standardization, customer satisfaction, and the required compliance level, a new approach was highly anticipated. And it is computer vision that has taken on the responsibility of ensuring real-time quality control. What is computer vision? What features, benefits, and practical uses does it offer? Let’s figure it out together in this article.

How Does Computer Vision Work in Automated Inspection and Quality Control?

Microsoft describes computer vision as an AI technology that allows machines to interpret, analyze, and extract meaningful information from images and videos.

It uses neural networks and machine learning to identify inconsistencies or other flaws in products. If we think of AI as an artificial brain, then computer vision is its eyes. But unlike human eyes, computer vision relies on objective data and algorithms, which enable it to inspect hundreds or even thousands of products per minute.

To better understand how computer vision works, let’s start by exploring its key components, namely, deep learning and neural networks, automated labeling, synthetic data, and real-time scalability.

Deep Learning and Convolutional Neural Networks

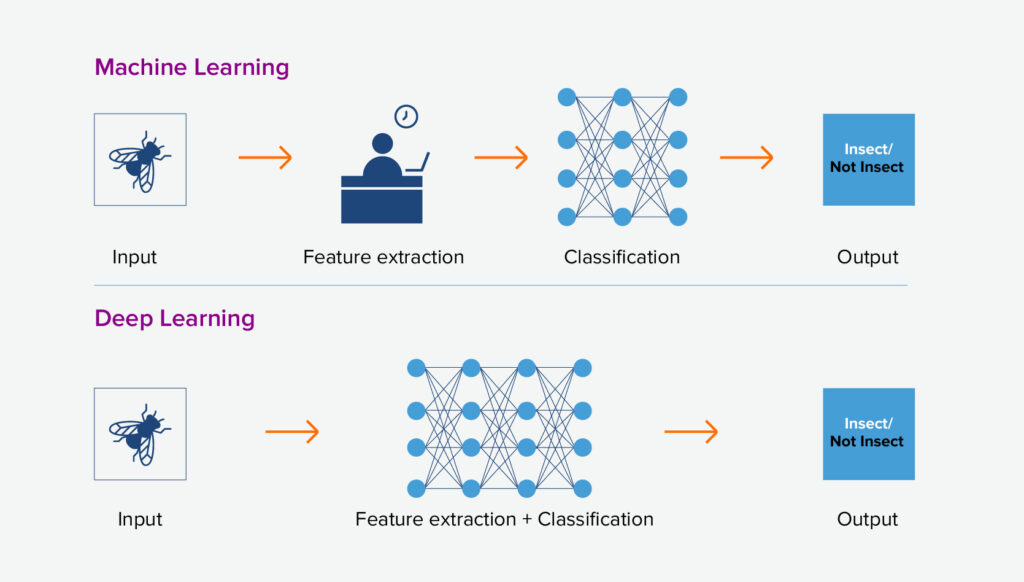

Initially, computer vision used machine learning algorithms. For example, when analyzing images, features of a specific image were manually extracted and fed into an ML system. Deep learning revolutionized the process by automatically extracting features without human help and processing them to produce the final result.

Source: tandfonline.com

Convolutional neural networks are a component of deep learning, and by learning hierarchical patterns, they allow computers to understand and extract data from visual objects.

Automated Labeling

With the help of ML models, automated labeling decreases the need for human input in data tagging. The “teacher” model, which is trained on manually labeled data, can predict labels for new data. This method strategically chooses the most valuable unlabeled data points for human review, which eventually optimizes the annotation process.

Synthetic Data

Computer vision models are trained with synthetic data, which is artificially generated through algorithms in simulated environments. For instance, game engines are used to create realistic 3D scenes. Basic methods of producing new data include cropping or adding noise to existing images. It is important to note that synthetic data provides error-free, precise labels, which is nearly impossible to achieve manually.

Real-Time Scalability

Real-time processing and scalability are essential performance requirements rather than mere components of computer vision. Through real-time monitoring, computer vision systems can quickly capture, analyze, and respond to the selected visual data within milliseconds. Despite performing thousands of inspections each hour, computer vision systems maintain a high level of accuracy, which makes them invaluable in fields such as electronics and automotive.

Human Vision vs. Computer Vision

Despite the clear similarities between the two terms, some differences greatly affect the speed, accuracy, and outcome of the automated inspection and quality control process.

| Human Vision | Computer Vision | |

| Perception | Sees and recognizes naturally through experience. | Detects and identifies via sensors and algorithms. |

| Mechanism | Eyes capture light; brain interprets images. | Cameras capture data; AI analyzes patterns. |

| Recognition | Instantly recognizes objects, even new ones. | Requires training data to classify objects. |

| Accuracy | Affected by fatigue and subjectivity. | Consistent, precise, and objective. |

| Speed | Slower, manual inspection. | Fast, scalable, real-time inspection and analysis. |

| Adaptability | Learns from experience and context. | Learns from data and algorithm updates. |

Computer Vision or Machine Vision?

In brief, machine vision is a subset of computer vision, mainly focused on industrial uses like robotic guidance. Computer vision is a wider area of AI that enables computers to interpret the visual world.

Both machine vision and computer vision look at visual inputs, but they are used differently and set up differently:

- Machine vision uses cameras, lenses, and computers to make decisions, usually as part of bigger systems, like spotting defects on a production line.

- Computer vision, on the other hand, can work on its own, using saved images or even synthetic ones, without needing a camera. It analyzes data to give results.

Computer vision often pulls out a lot of information about objects, while machine vision is more about quickly and precisely finding specific features in controlled environments.

Top Benefits of Computer Vision in Quality Control

With computer vision tools, quality control is more precise and quicker than relying on human vision. However, its full range of benefits is much greater.

Faster Defect Detection and Defect Reduction

Computer vision helps us spot problems like surface cracks, scratches, or material flaws much earlier than they become bigger issues. Catching these defects early means manufacturers can reduce waste, avoid redoing work, and maintain steady product quality. This way, faulty products never reach the customer.

Improved Dimensional Accuracy

Computer vision systems use high-resolution imaging and AI-powered measurements to ensure each part meets exact tolerances. This way, they guarantee that every component adheres to strict dimensional standards and reduces errors usually caused by manual checks. The result is more consistent quality, higher accuracy, and fewer deviations in production.

Customizable Inspections for Non-Uniform Products

Products such as glass panels, textiles, or roofing materials often exhibit natural variations, which can make traditional inspections challenging. Computer vision systems are trained on synthetic data, which is why they allow us to recognize acceptable irregularities and still catch genuine defects. This flexibility means we can automate inspections even for products that are non-uniform or custom-made.

Enhanced Process Optimization and Reduced Costs

Computer vision isn't just about inspecting products because it's monitoring the entire production process. It catches equipment problems or inefficiencies and ensures faster defect detection, which helps reduce downtime, extend the lifespan of machinery, and improve workflows. This proactive strategy reduces operational costs and enhances overall productivity.

Computer Vision for Quality Sorting and Categorizing Products

Automated vision systems can quickly sort and categorize items by their shape, color, or surface quality. They tend to be faster and more reliable than manual inspections and provide consistent results even when they need to analyze large volumes of objects, images, etc. This automation accelerates packaging and distribution processes without sacrificing quality.

Dimensional Measurement and Gauging for Consistent Product Dimensions

Vision-based gauging ensures every item matches the required measurements with remarkable precision. Dimensional check automation enables manufacturers to eliminate human error and expedite quality verification. This consistency helps maintain brand reliability and reduces product returns due to off-spec dimensions.

Real-Time Monitoring Object Recognition and Classification

AI-powered cameras monitor each product as it travels through the production line. They quickly spot any issues like misalignments, missing parts, or assembly mistakes, so teams can jump in right away. This instant feedback, powered by computer vision for inspection and quality control in manufacturing, helps make better decisions, stops problems from spreading, and makes the whole production process more efficient.

Real-World Applications of Computer Vision in Quality Control

Source: turing.com

From theory to practice. Just as AI has become an essential part of many processes across various fields, computer vision is also gaining momentum. Its examples include human detection in computer vision, image classification, pose estimation, and more. To narrow down these examples, let’s focus on several top industries using computer vision for automated inspection and quality control.

Advancing Healthcare with Computer Vision

Healthcare is a field where speed and accuracy directly impact human lives. Computer vision allows machines to analyze medical images and live video, helps clinicians diagnose conditions earlier, and supports ongoing patient monitoring. Besides, its capabilities span across key areas such as:

- Surgical guidance: Real-time inspection vision tracking enhances precision, reduces risks, and supports minimally invasive procedures.

- Patient monitoring: Smart vision systems detect movement patterns, falls, or distress signals.

- Early disease detection: AI-powered image analysis spots subtle anomalies in X-rays, MRIs, and CT scans faster and with higher accuracy.

- Workflow optimization: Automating imaging review and patient tracking frees clinicians to focus on higher-value tasks.

- Medical training and simulation: Computer vision aids in realistic surgical simulations and performance assessments.

AI-Powered Vision Systems for Smarter Logistics

Logistics is another area greatly impacted by AI, especially computer vision. These systems revolutionize how goods are inspected, routed, and managed from the warehouse to the delivery hub. They enable:

- Automated inspection of packages for defects or mis-labels to improve quality control and reduce returns.

- Real-time monitoring of inventory and shipments to deliver visibility into stock levels and item movements

- Enhanced safety and operational efficiency by monitoring work zones, identifying hazards such as forklift-pedestrian proximity, and alerting staff before incidents occur.

Automotive Industry

AI-powered vision systems are guiding the automotive industry into a new era of intelligence and safety. Computer vision provides “eyes” on everything from the factory floor to the driver’s seat. With its assistance, cars start see, understand, and respond.

- Smarter, safer driving: Advanced Driver Assistance Systems (ADAS) and autonomous vehicles use cameras and sensors to detect lanes, traffic signs, pedestrians, and other vehicles in real time.

- Flawless manufacturing: Automated visual inspections ensure faster defect detection, assembly errors, and misaligned components before cars even leave the factory.

- Watchful eyes on the driver: In-cabin monitoring tracks attention, posture, and behavior, issuing alerts or taking preventive actions to reduce accidents.

Electronics Manufacturing

With computer vision, electronics manufacturing can spot imperfections invisible to the human eye and keep production lines running like clockwork. These intelligent systems are transforming standards of quality and efficiency across various devices, from smartphones to circuit boards.

- Detecting hidden defects: Instantly detecting soldering errors, misaligned chips, or damaged components before products leave the line.

- Verifying assembly accuracy: Ensuring every tiny part is perfectly in place, thereby reducing costly rework and recalls.

- Optimizing production flow: Monitoring processes, identifying bottlenecks, and increasing throughput on high-volume electronics lines.

Technical Aspects and Implementation of Computer Vision

Implementing computer vision is like teaching machines to see, think, and understand the world around them. Imagine giving a robot a pair of super-smart eyes, which are a blend of powerful hardware, clever software, and cutting-edge AI models working together.

At the hardware level, features such as high-resolution cameras, GPUs, and edge devices provide the speed and accuracy needed to capture and analyze massive amounts of visual data almost instantly.

On the software side, advanced algorithms process images, detect objects, segment scenes, and track movement. This transforms raw pixels into useful insights. True magic happens with machine learning and deep learning models, including convolutional neural networks with their logical framework and vision transformers, which teach the system to recognize patterns, identify objects, and improve over time through experience.

When these pieces come together thoughtfully, they form a powerful system capable of smarter manufacturing, safer logistics, better healthcare workflows, and even innovations in automotive technology. It’s about creating systems that can predict issues, improve processes, and provide insights faster and more accurately than humans ever could.

The Future of Computer Vision in Quality Control

Computer vision in quality control is here to stay, and that’s for sure. More manufacturers are adopting AI real-time inspection and insights, edge intelligence, and agile workflows for faster defect detection, reducing waste, and making every production line smarter.

Edge AI for IoT Devices

With edge AI integrated into IoT devices directly on the factory floor, vision systems can quickly identify defects within milliseconds and respond right there on the spot without needing to send data to the cloud. This means issues can be corrected immediately, helping to reduce mistakes and increase overall output.

Sustainability and Waste Reduction

Fewer defects and earlier detection translate directly into less material usage, less scrap, and lower energy cost. Industrial quality control becomes a contributor to ESG goals, not just a means to achieve cost savings. Computer vision systems have already helped manufacturers cut defect rates by up to 80%, which significantly reduces waste and environmental impact.

Agile Manufacturing

Combining computer vision with IoT and edge AI makes manufacturing more adaptable and responsive. It allows production lines to quickly adjust to new products, smaller batches, or changing specifications. As a result, companies can react faster to market demands without sacrificing quality or efficiency.

Optimizing Your Quality Control with Computer Vision

To truly optimize quality control, it’s better to start with inspections that have the highest impact, deploy edge-enabled vision systems for real-time monitoring, incorporate insights into process analytics, and continuously update AI models to identify new defect types. This way, quality control becomes a proactive strategic tool rather than just a passive checkpoint, boosting efficiency, reducing waste, and supporting sustainability.

Summing Up

Computer vision is no longer a futuristic concept. Now it’s a practical, game-changing tool for quality control across industries. Computer vision systems are already helping companies produce higher-quality products faster and smarter, and turn their quality control processes into a strategic advantage.

At Svitla Systems, we assist businesses in leveraging AI across various areas to streamline operations, enhance accuracy, and minimize waste. Discover our expertise in deploying AI-driven solutions and let us help you stay ahead in this competitive market.

![[Blog cover] Agentic AI vs traditonal automation](https://svitla.com/wp-content/uploads/2025/09/Blog-cover-Agentic-AI-vs-traditonal-automation-560x310.jpg)