Business operations face substantial hurdles from supply chain disruptions, vendor monitoring, shifting consumption trends, and volatile material costs. These issues underscore the need for implementing enhanced supply chain management systems.

Using predictive analytics turns into a crucial instrument when tackling logistics challenges. Companies can forecast disruptions using data-led predictions, improve demand planning, and refine decision-making. This ability switches firms over from just reacting to stopping issues before they start. Keeping up with the competition in our complicated worldwide supply webs is a big deal.

We've previously examined predictive analytics applications in the finance sector and investment strategies. This article will analyze its role in logistics and demonstrate how it enhances demand forecasting and risk management. Let's begin.

What is Predictive Analytics?

Predictive analytics uses past information to guess what might happen in the future. It combines old data, math, and computer learning to make these guesses. Companies use this method to find significant patterns in their information. These patterns show possible risks and chances for success.

Predictive analytics uses various methods to study large sets of data from many places. These methods include:

- Regression analysis looks at how different factors relate to each other.

- Neural networks mimic how human brains work to find patterns.

- Decision trees help make choices step-by-step.

With the help of these methods to process data, predictive analytics turns raw information into useful insights that guide business actions.

What is Demand Forecasting?

Logistics demand forecasting lets businesses predict goods, storage, and transportation services needs in the future. Companies use historical data on orders, deliveries, customer behavior, and current market trends to predict consumer demand. This understanding allows businesses to adapt quickly to new situations, as seen during the COVID-19 pandemic.

Demand forecasting aims to identify potential scenarios a company might face in its logistics needs. This gets important during global disruptions that test supply chain strength.

How does Demand Forecasting Work?

Combining quantitative and qualitative approaches helps create solid insights throughout the supply chain. By using both, companies can better predict what their customers will need.

Qualitative data comes from external and internal sources. External sources include news reports, cultural and social trends, competitors, and market research. In turn, internal sources mainly mean customer feedback and reviews.

This data provides valuable context about market movements, industry trends, and customer opinions. While it doesn't offer exact numbers, it gives rich insights into how organizations, industries, and individuals think and act.

Quantitative data is gathered internally from sales numbers, peak shopping periods, inventory levels, and search analytics. Advanced analytics and AI/ML help extract meaningful insights from large datasets.

The strength of demand forecasting lies in combining these methods:

- Qualitative insights help predict future macro trends and market movements

- Quantitative insights provide an understanding of the current customer base and near-future demand fluctuations

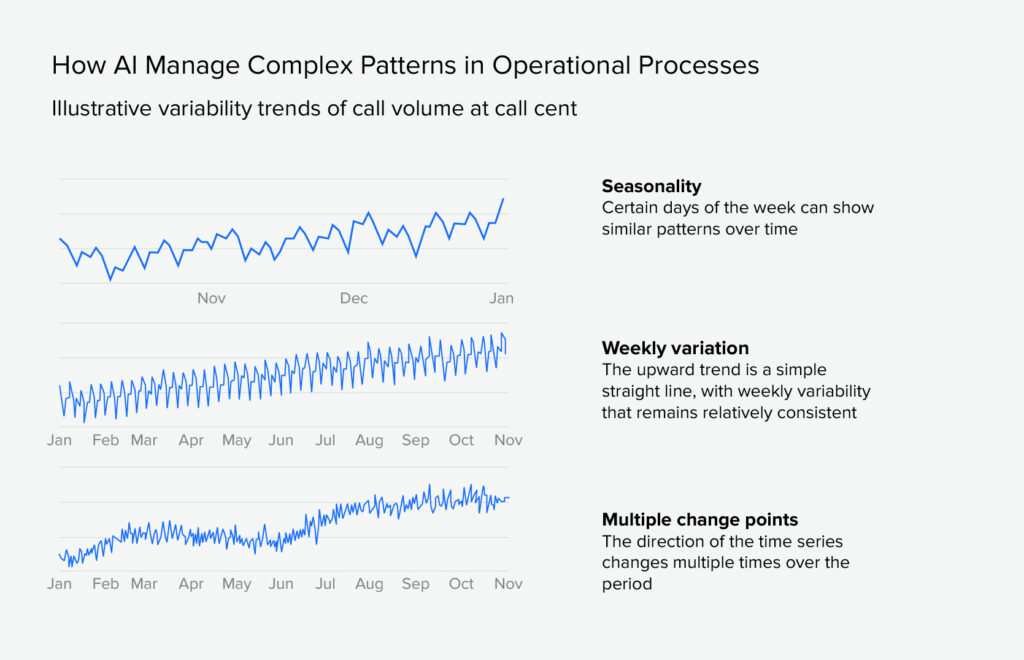

Source: McKinsey & Company

Role of Predictive Analytics in Demand Forecasting

Predictive analytics is now a key part of planning for demand. This approach focuses on two critical aspects: generating accurate forecasts and optimizing operations.

Predictive Analytics for Accurate Forecasts

Historical data, market patterns, and key variables enhance the accuracy of predictive analytics. This methodology uncovers concealed consumption patterns and forecasts future requirements with high precision.

The analysis begins by examining past sales records to detect patterns and correlations. This information is then integrated with market intelligence, including competitor analysis, economic indicators, and consumer behavior. The result is a comprehensive demand forecast model that continuously updating and refines itself.

These projections help companies decide strategically about stock control, supply chains, and manufacturing planning. Beyond forecasting, businesses can optimize resource distribution, reduce wastage, and enhance operational performance.

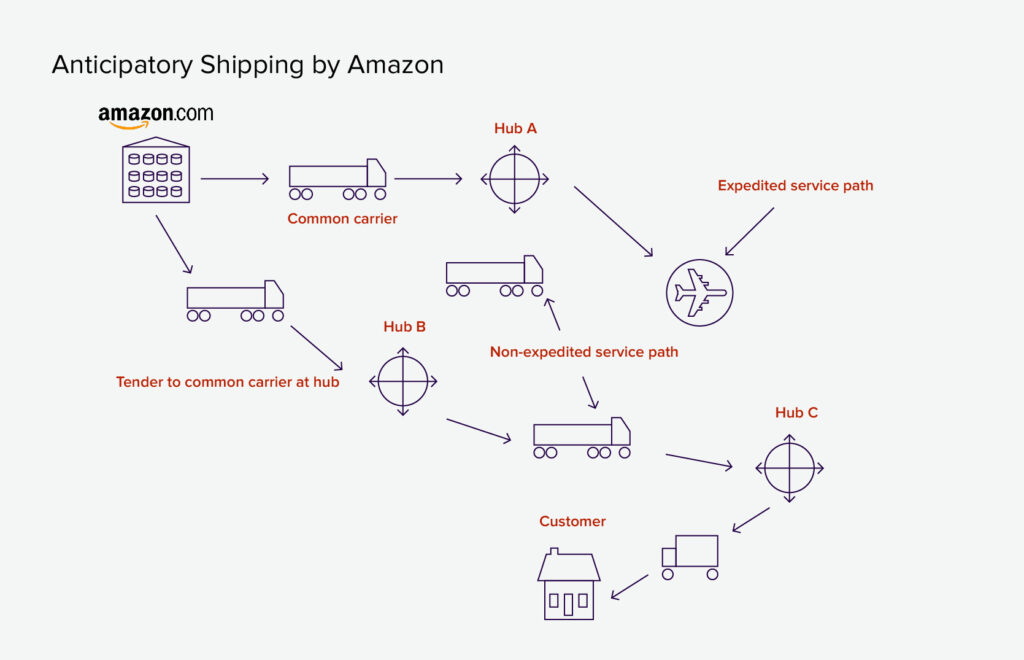

A notable illustration is anticipatory shipping by Amazon. This approach involves positioning in-demand products in strategic warehouse locations before purchase to minimize delivery duration. It also optimizes delivery route and fleet utilization, promoting efficiency and environmental responsibility in final-mile distribution.

Source: Google Patents

Streamlining Operations with Predictive Analytics

Predictive analytics does more than just guess the future. It helps make work easier by looking at old information. It finds problems and ways to do things better when planning what customers want. This allows companies to improve how they get products to people, work faster, and save money.

One way it helps is by seeing when people buy more at certain times of the year. This lets businesses plan. They can make or get more products when they know people will want them. They also avoid having too much when people don't need as much.

Predictive analytics also helps set good prices. It looks at past sales and what's happening in the market. This shows how changing prices affect what people buy. Companies can then choose prices that make the most money while staying competitive.

It also helps understand different groups of customers. By seeing what each group likes to buy, businesses can make better plans for selling and marketing to them. This makes customers happier and helps sell more.

UPS shows how predictive analytics can help with deliveries with its On-Road Integrated Optimization and Navigation (ORION) platform. The system's Dynamic Optimization feature continuously recalculates delivery routes throughout the day, adapting to changing traffic conditions, pickup commitments, and delivery orders. This advanced predictive analytics solution result saves UPS from $100 to $200 million.

Benefits of Predictive Analytics in Demand Forecasting

Predictive analytics has emerged as a powerful tool in retail demand forecasting, offering significant advantages to businesses that harness its potential. Let's explore this technology's key benefits to the retail sector.

Expense Management

Organizations can sustain ideal stock levels by evaluating consumer patterns and industry shifts. This strategy minimizes stockout and surplus inventory risks, reducing missed sales and excess storage expenses.

Enhanced Forecast Accuracy

Predictive analytics helps businesses guess what customers will buy more accurately by looking at how much people bought before, what's happening in the business world, and how customers usually shop. When businesses can better guess what people will buy, they can avoid running out of products or having too many products that don't sell. This way, companies can keep just the right amount of products, ensuring they have what customers want when they want it, without wasting money on extra stuff that might not sell. This approach improves customer satisfaction and boosts the company's efficiency and profitability.

Improved Decision-Making

Predictive analytics helps stores make better choices about how they run their business. By looking at up-to-date information, stores can quickly change prices, plan sales, and manage their stock. This smart way of working helps stores run more smoothly and save money. It also lets them spot new trends and opportunities in the market faster. When stores use this information well, they can improve their business. They can give customers what they want when they want it, which makes the company and its customers happy.

Cost Reduction and Operational Efficiency

Predictive analytics helps to optimize inventory management by preventing overstocking and stockouts. This way, it cuts waste and storage expenses. Through precise demand forecasting, supply chain processes become more efficient with less necessity for urgent adjustments and rush deliveries. These improvements generate cost reductions and allow retailers to deploy their resources strategically and enhance profitability.

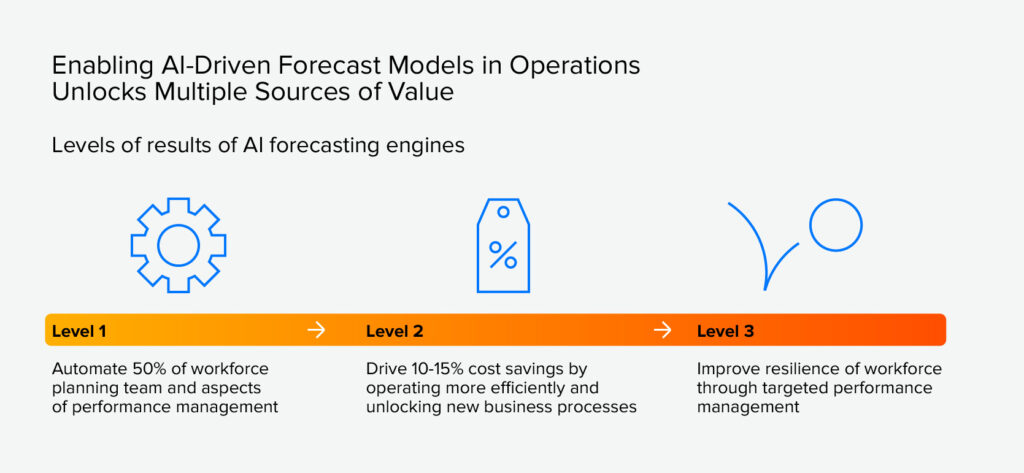

Recent research reveals that AI-based demand forecasting lowers supply chain deviations by 20% to 50%, with a 65% improvement in operational performance thanks to fewer lost sales and unavailability of products. So you can deliver savings of 10% to 15%. At the same time, it will improve your recruitment decisions and probably even your operational adaptability, as AI forecasting systems are able to automate 50% of workforce-management operations.

Source: McKinsey & Company

Personalization and Customer Satisfaction

Predicting what customers want helps businesses improve their services. Companies can look at what people bought before and how they shop. This information lets them offer better products and services to each customer.

Companies can send special offers to specific customers, suggest products a customer might like, and set different prices for different groups of people. When companies do this well, customers are happier and more likely to come back. They can find what they need when they need it. This makes them regular customers, which helps the business grow.

Challenges in the Predictive Analytics Implementation

While offering numerous advantages, integrating predictive analytics into demand planning presents several hurdles:

Data Quality and Management

The foundation of success lies in data integrity and management. Predictive analytics depends on accurate, consistent, and current information. Organizations require sophisticated infrastructure and streamlined data handling protocols to maintain information accuracy and availability. This typically necessitates spending on data storage systems and establishing comprehensive data management standards.

Skilled Professional Shortage

A big challenge is finding enough skilled people to do the job. Predictive analytics needs workers who know about the industry, are good at mathematics and can work with data. Organizations frequently must enhance their workforce's skills or recruit specialists to address this expertise deficit.

Conclusion

Predictive analytics solutions have become core to modern supply chain operations and demand planning. Organizations can improve operational performance, forecasting accuracy, and customer service by adopting data-driven and fact-based approaches. However, implementing these systems proves to be quite a technical challenge for businesses, particularly regarding data management and workforce recruitment.

Svitla Systems offers through and through solutions for such industry needs. Our skilled data scientists and engineers develop predictive analytics solutions tailored to your supply chain and logistics needs. Contact us to learn how our technical expertise can transform your forecasting capabilities through advanced predictive analytics deployment.